| Processing Stage | Key Equipment | Conveyor Type | Functional Features |

|---|---|---|---|

| Raw Material Handling | Flour sifter, Liquid dosing | Stainless steel chain conveyor | Rust-proof, dust-resistant, easy residue removal |

| Mixing & Fermentation | Spiral mixer, Proofing box | N/A (Direct container transfer) | — |

| Dividing & Shaping | Dough divider, Rounder | Food-grade PU belt | Anti-stick surface, textured for grip |

| Final Proofing | Multi-level proofer | Mesh belt conveyor | High humidity (80%) and temperature resistance, breathable |

| Baking | Tunnel/rotary oven | PTFE-coated mesh/stainless steel | Heat-resistant (250°C+), non-stick |

| Cooling | Cooling tower | Modular plastic belt | Ventilated design for rapid cooling |

| Slicing & Packaging | Automatic slicer, Packer | Timing belt/anti-static PVC | Precise positioning, crumb-free operation |

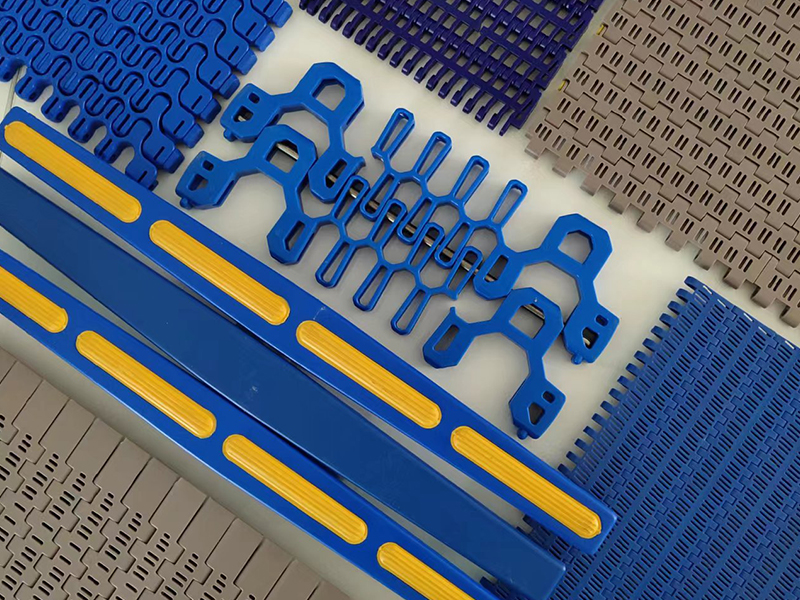

| Material Type | Application | Advantages | Limitations |

|---|---|---|---|

| Food-grade PU | Dough transfer, shaping | Oil-resistant, easy cleaning | Not heat-resistant (<100°C) |

| PTFE-coated | Baking zone | Non-stick, 260°C tolerance | Higher cost |

| Stainless steel chain | Heavy-duty raw material handling | Durable, corrosion-resistant | Requires lubrication |

| Modular plastic belt | Cooling, packaging | Washable, quick disassembly | Not for sharp objects |

| Silicone belt | High-sanitation areas | Antibacterial, flexible | Prone to cuts |

The selection of conveyor system for bread production line should focus on three core aspects: product characteristics, hygiene requirements, and production capacity goals, combined with the trends of intelligence and energy conservation. It is recommended to match equipment materials and automation levels according to actual needs, and strictly follow food grade safety standards to achieve efficient, stable, and compliant production.

Empower your journey to build a thriving machine business empire with our comprehensive solutions.

We use high-quality materials to ensure ease of use and hygiene, meeting the high standards required by various industries.

The professional team provides customers with a full range of effective solutions and after-sales services.

At here, it’s all about giving the clients thebest quality products.