Secondary packaging refers to the process of centrally wrapping, bundling or boxing products that have completed primary packaging (single or multiple small packages) according to the predetermined quantity and arrangement (such as grouping, palletizing, and boxing) through automated equipment to form an “intermediate packaging body” that is convenient for subsequent handling, warehousing, and large-scale distribution. This is a key process that connects front-end packaging with back-end logistics.

Significantly Improve Efficiency: Say goodbye to tedious and inefficient manual palletizing, strapping, and bagging. The automated mid-pack machine operates at speeds far exceeding manual labor, easily meeting high-volume production demands and significantly shortening packaging cycles.

Substantially Reduce Costs: Reduce reliance on manual labor, lowering both labor and management costs. Precisely control the amount of packaging materials (such as shrink film, stretch film, cartons, and cardboard) used, minimizing waste. Reduce packaging damage and product loss caused by improper manual handling.

Ensure Product Safety and Quality: Stable and consistent automated operation eliminates the risk of contamination from human contact. Stable secondary packaging (such as heat shrink wrap, wrapping, and boxing) effectively protects the product from crushing, collisions, dust, and moisture during storage and transportation.

Improve Standardization and Image: Ensure uniform specifications and a neat and aesthetically pleasing appearance for each mid-pack, enhancing the brand’s professional image and facilitating warehouse management and terminal display.

Flexible Adaptability to Diverse Needs: Modern mid-pack packaging machines offer exceptional flexibility, easily adapting to varying product specifications, packaging formats (such as shrink wrap, film wrapping, automatic cartoning/boxing, bagging, overwrapping), and packaging quantities, meeting the flexible production needs of high-variety, small-batch production.

Seamless Integration with Automated Production Lines: As a key component of smart factories, mid-pack packaging machines seamlessly connect front-end packaging machines with back-end palletizing/conveying systems, achieving full automation and informationization from production to warehousing. They are crucial equipment for creating unmanned or reduced-staff workshops.

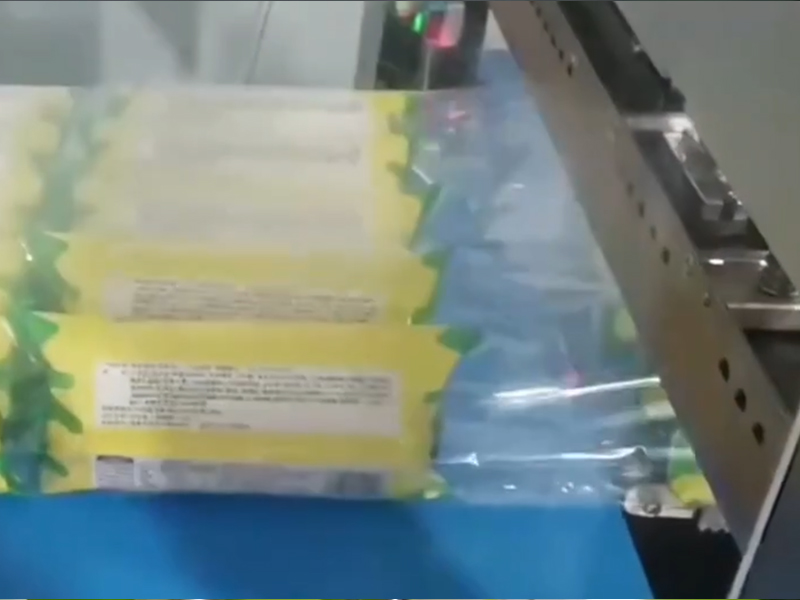

Food and beverage industry: Bottled water/beverages are packaged in shrink film, bagged snacks are wrapped in multiple packages, canned food is fixed in trays with wrapping film, boxed milk is automatically packed, etc.

Daily chemical cleaning industry: Bottled shampoo/shower gel is packaged in shrink film, bagged washing powder/laundry liquid is packaged in multiple packages, soap is wrapped in film, etc.

Pharmaceutical and health care products industry: Pharmaceutical aluminum-plastic panels/bottled medicines are packaged in boxes or shrink-wrapped, and health care product gift boxes are automatically packed.

Hardware and electronics industry: Small tools and parts are packaged in bags or boxes, and electronic components are packaged in trays with wrapping film.

Other industries: Books, stationery, toys and other products that need to be packaged collectively.

Empower your journey to build a thriving machine business empire with our comprehensive solutions.

We use high-quality materials to ensure ease of use and hygiene, meeting the high standards required by various industries.

The professional team provides customers with a full range of effective solutions and after-sales services.

At here, it’s all about giving the clients thebest quality products.